GKN Additive (Forecast 3D) provides a full spectrum of 3D printing, rapid machining, and quick-turn tooling solutions for the highest quality prototyping and production. A rarity in the marketplace, we run all of our manufacturing equipment in-house and have designed and built much of it ourselves. As an SAP Additive Manufacturing partner and the official West Coast MJF by HP Experience Center, we are uniquely qualified in both prototype and production manufacturing.

OUR SERVICES

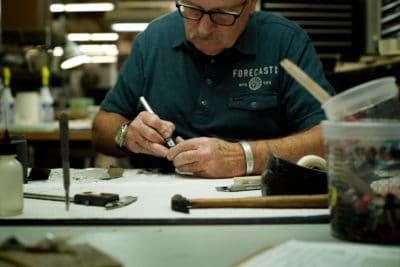

AMERICAN CRAFTSMANSHIP

WORLD-CLASS ADDITIVE EXPERIENCE

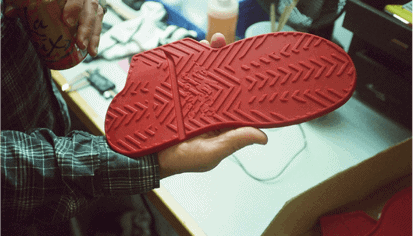

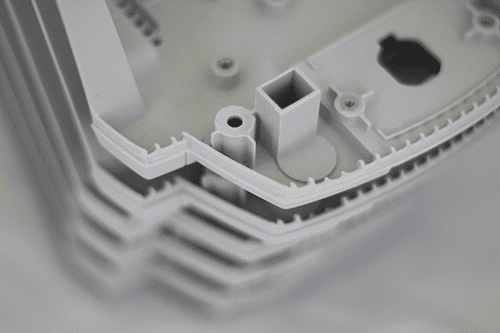

For more than 25 years, we have been providing industrial 3D printing, short-run manufacturing, and high-volume production services to empower companies to speed their product development cycle. We focus on bringing your ideas to life faster than you thought possible using the best in Additive and Digital Manufacturing technologies. Capabilities include MJF (Multi Jet Fusion) by HP, SLA (Stereolithography) models, PolyJet high-precision color 3D printing, FDM (Fused Deposition Modeling) patterns in engineering grade thermoplastics, Metal Laser Sintering by SLM for additive metal parts, and our Urethane Casting tooling for high quality urethane castings.

We provide 3D printing and custom manufacturing to customers in a variety of industries. From a quick turn, intricate surgical device to a large intake manifold for a jet engine, to a production run of 4,000 radomes, we have the technology and experience to deliver. As the West Coast experience center for HP, our growth from a world-class prototype shop to a 50,000 square foot modern 3D manufacturing facility, our team is ready to help you leverage our Additive Manufacturing capabilities.

With the most innovative 3D Printing technologies available, coupled with extraordinary service and craftsmanship, we aim to provide you with the ideal manufacturing experience to fit your specific need, every time.