PROCAST - RTV URETHANE CASTING & MOLDING

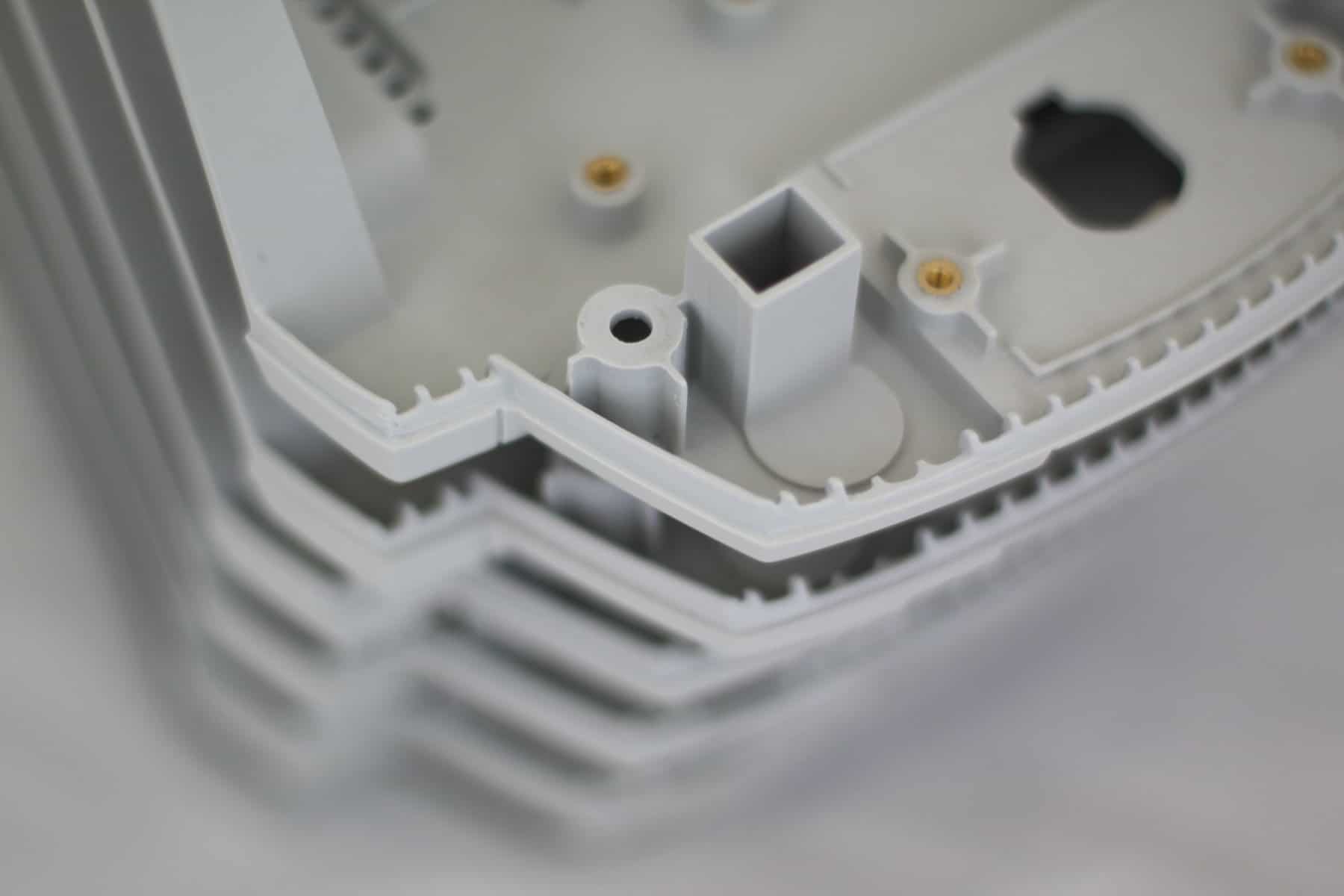

For a short-run of functional and aesthetically pleasing production parts, ProCAST RTV - our proprietary Urethane Casting process - is the next step after a 3D printed prototype. The ProCAST process utilizes SLA, FDM, or PolyJET master model patterns to create the highest quality cast urethane parts available.

Our ProCAST Urethane Casting process is ideal for higher quantities (from 10 to 1000) and creates parts in both color and texture, giving us the ability to create custom color matched parts with the texture pulled from the mold cavity for a repeatable quality output. Furthermore, we have one of the largest casting chambers in the US, with the capabilities to produce very large, void free cast parts.

One of our flagship offerings, each ProCAST part goes through a 5 point inspection plan at 3 separate manufacturing stages, to control the process and produce aesthetically pleasing and geometrically toleranced end use parts. For projects with in-mold and overmold requirements, we offer a variety of Shore A rubber materials, and in-mold fiber additives to strengthen parts by a factor of 10.

BENEFITS

- Scalability - optimal for low to mid volume production

- High quality aesthetics achievable

- Material selection: over 50 resins in stock

- Size: very large part size capability

- Over-mold / co-mold specialists

- Custom finishes: cast in any color & texture

- Durability: ability to operate in demanding environments

APPLICATIONS

- Functional prototypes and end-use parts

- Batch production medical devices

- Aircraft interior parts

- Consumer products

- Specialty overmold requirements

- Complex prototypes

- Aesthetic marketing models

TECHNICAL SPECIFICATIONS

| Standard Lead Time | 4 - 6 days for first article |

| Standard Accuracy | +/- .007" first inch plus .003" per inch thereafter |

| Minimum Wall Thickness | Let one of our project engineers review your CAD. We have done fine features as fine as toothbrush bristles. |

| Maximum Part Size | The largest RTV capabilities in the US - largest part built to date is 8' x 4' x 3' |

| Typical Quantities | Mold yields up to 25 quantity per tool (varies by geometric complexity and material cast) |

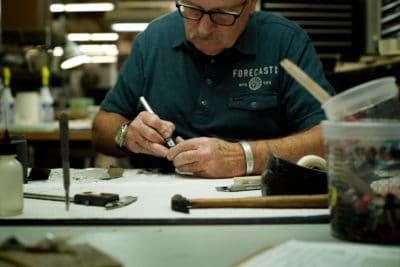

| Finishes | The sky is the limit. We have two production paint booths and a team of master craftsmen that can produce very high quality options. We quantify our aesthetic options as Engineering, Engineering Plus, Forecast Quality Finish. |

MATERIALS

- UABS 85 - High Impact

- UABS 86 UV - Production

- UABS HIB - Ultra High Impact Black

- UABS FR3 - Flame Retardant

- UOptic - Waterclear

PROCAST FINISHES

ENGINEERING

A part that has visible process layer lines and minimal post processing that is specific to the engineer who is most concerned with cost savings, faster lead times, and proofing out design. These parts have minimal finish done to additive master models and cast parts may have signs of color / surface variations inherent to the RTV process.

ENGINEERING PLUS

This finish is designed for applications where the strength and cast in color of a part is important, but the high level of aesthetics found in our Forecast Quality is not necessary and lead time is more important. These parts may have imperfections due to process; small scratches, variations in cast color and has minimal visible layer lines at arm’s length on outside surfaces.

FORECAST QUALITY

A part that is typically representative of our heavy emphasis on aesthetics with very minimal process defects; slight imperfections on the castings, minimal variations in cast color and no visible layer lines on show surfaces.

FORECAST QUALITY PLUS

Parts deemed as critical finished to spec. Tight tolerances, Custom Finishes, etc.. Please specify in

notes and include any mechanical drawings and/or available BOM's

Not Ready for a Quote?

Let's talk about your project!