MULTI JET FUSION MATERIALS

MATERIAL LIST

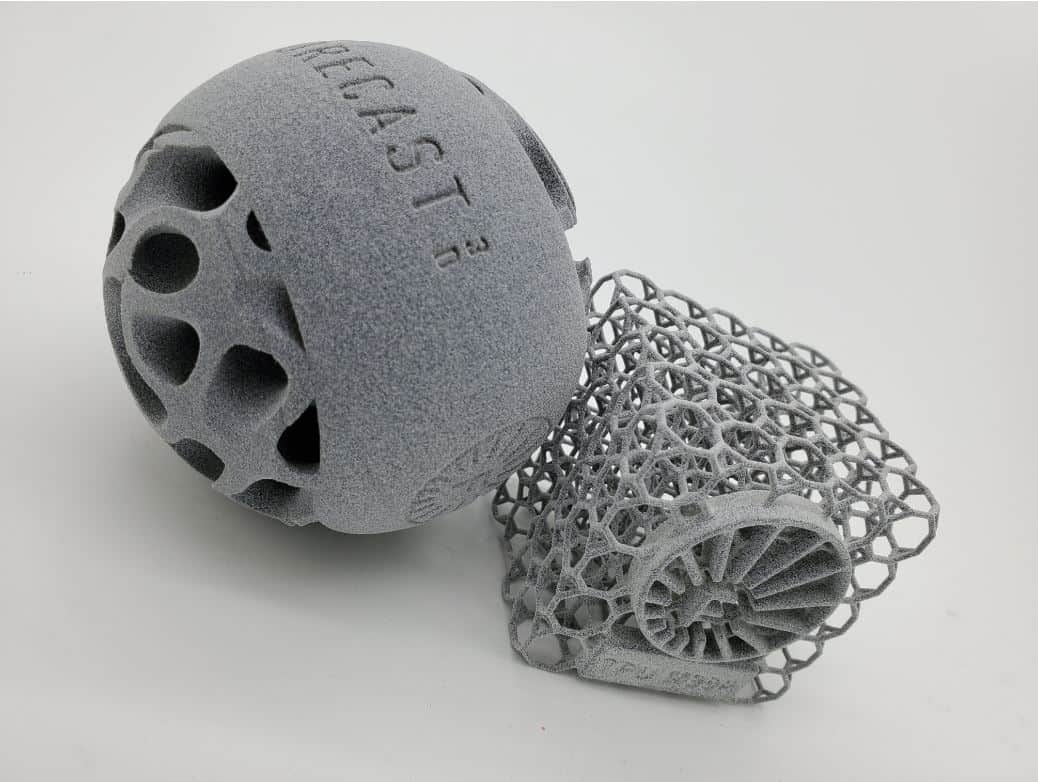

PA 12 (Natural Gray)

An engineering grade thermoplastic for high-density parts with extreme dimensional accuracy and fine detail for functional prototyping and final parts. This strong thermoplastic is ideal for complex assemblies, lattice structures, housing, enclosures and connectors, and optimal for post finishing processes - has excellent chemical resistance to oils, greases, aliphatic hydrocarbons and alkalies.

PA 12 GB - GLASS BEAD

This 40% glass bead filled thermoplastic material produces stiff, functional parts. PA 12 GB has both optimal mechanical properties and high reusability, and provides dimensional stability. It's ideal for functional applications requiring high stiffness like enclosures and housings, fixtures, and tooling across a variety of industries.

PA 12 W (PURE WHITE)

This engineering-grade thermoplastic yields high-quality functional production parts in a premium white finish. PA 12 W (Pure White) is ideal for strong, complex parts with balanced property profiles and strong structures. In addition to high consistency, this robust material has high reusability. Designed for parts across industries such as healthcare and consumer goods, with applications such as prosthetics, medical equipment, fashion and wearables, and household appliances.

PA 11

This thermoplastic delivers optimal mechanical properties, and is known for producing strong, ductile, functional parts. PA 11 also provides excellent chemical resistance and enhanced elongation-at-break. Ideal for impact resistance and ductility for prostheses, insoles, sports goods, snap fits, living hinges, and more.

TPU 88A – BASF Ultrasint® TPU01

This MJF specific thermoplastic from BASF offers high wear/abrasion resistance, and is ideal for applications needing rubber-like flexibility and excellent shock absorption. TPU 88A - BASF Ultrasint 3D prints with high accuracy and detail, in addition to having smooth surfaces.

HP 3D High Reusability PP enabled by BASF4

Provides the optimal balance between performance and cost. Get the same properties as many commonly used PPs with this genuine polypropylene material and accelerate your product development process using the same prototyping material as the final part. Versatile material with excellent chemical resistance, low moisture absorption, and outstanding welding capabilities. Ideal for a wide range of automotive, industrial, consumer goods, medical applications.

Regarding PA 12:

*Outgassing results are specific to the test parameters outlined. Custom test parameters specific to your application may yield different results.

**Biocompatibility for HP PA 12 was determined through;

1. USP Class I-VI including irritation, acute systemic toxicity, and implantation

2. Cytotoxicity – ISO 10993-5, Biological evaluation of medical devices – part 5: Tests for in vitro cytotoxicity, and

3. Sensitization – ISO 10993-10, Biological evaluation of medical devices – Path 10: Tests for irritation and skin sensitization.

**Forecast does not certify or guarantee that HP PA 12 is biocompatible in your specific process and application. It is each customers responsibility to determine and test if HP 3D600 fusing, detailing agents, and HP 3D HR PA 12 powder is safe and technically suitable for the intended application in accordance to applicable FDA regulations.

***RoHS & Reach – HP PA 12 fully complies with RoHS and Reach regulations.

MJF FINISHES

PA 12 (NATURAL GRAY) TECHNICAL DATA

MECHANICAL PROPERTIES

| Properties | Test Method | English | Metric |

| Tensile Strength, Max Load9, XY | ASTM D638 | 6960 psi | 48 MPa |

| Tensile Strength, Max Load9, Z | ASTM D638 | 6960 psi | 48 MPa |

| Tensile Modulus9, XY | ASTM D638 | 247 ksi | 1700 MPa |

| Tensile Modulus9, Z | ASTM D638 | 261 ksi | 1800 MPa |

| Elongation at Break9, XY | ASTM D638 | 20% | 20% |

| Elongation at Break9, Z | ASTM D638 | 15% | 15% |

| Izod impact notched (@ 3.2 mm, 23ºC), XYZ | ASTM D256 Test Method A | 3.5 KJ/m2 | 3.5 KJ/m2 |

| Flexural strength (@ 5%)10, XY | ASTM D790 | 9425 psi | 65 MPa |

| Flexural strength (@ 5%)10, Z | ASTM D790 | 10150 psi | 70 MPa |

THERMAL PROPERTIES

| Properties | Test Method | English | Metric |

| Heat Deflection Temperature (@ 0.45 MPa, 66 psi), XY | ASTM D648 Test Method A | 347°F | 175°C |

| Heat Deflection Temperature (@ 0.45 MPa, 66 psi), Z | ASTM D648 Test Method A | 347°F | 175°C |

| Heat Deflection Temperature (@ 1.82 MPa, 264 psi), XY | ASTM D648 Test Method A | 203°F | 95°C |

| Heat Deflection Temperature (@ 1.82 MPa, 264 psi), Z | ASTM D648 Test Method A | 223°F | 106°C |

GENERAL PROPERTIES

| Properties | Test Method | English | Metric |

| Powder melting point (DSC) | ASTM D3418 | 369°F | 187°C |

| Particle size | ASTM D3451 | 60 μm | 60 μm |

| Bulk density of powder | ASTM D1895 | 0.425 g/cm3 | |

| Density of parts | ASTM D792 | 1.01 g/cm3 |

| Certifications: |

| USP Class I-VI and US FDA guidance for Intact Skin Surface Devices, RoHS11, EU REACH, PAHs |

PA 12 GB - GLASS BEAD TECHNICAL DATA

MECHANICAL PROPERTIES

| Properties | Test Method | English | Metric |

| Tensile Strength, Max Load7, XY, XZ, YX, YZ | ASTM D638 | 4351 psi | 30 MPa |

| Tensile Strength, Max Load7, ZX, XY | ASTM D638 | 4351 psi | 30 MPa |

| Tensile Modulus7, XY, XZ, YX, YZ | ASTM D638 | 363 ksi | 2500 MPa |

| Tensile Modulus7, ZX, XY | ASTM D638 | 392 ksi | 2700 MPa |

| Elongation at Break7, XY, XZ, YX, YZ | ASTM D638 | 10% | 10% |

| Elongation at Break7, ZX, XY | ASTM D638 | 10% | 10% |

| IZOD Impact, notched (@ 3.2 mm, 23°C), XY, XZ, YX, YZ, ZX, ZY | ASTM D256 Test Method A | 3 KJ/m2 | 3 KJ/m2 |

THERMAL PROPERTIES

| Properties | Test Method | Temp | |

| Heat Deflection Temperature (@ 0.45 MPa, 66 psi), XY, XZ, YX, YZ | ASTM D648 Test Method A | 345°F/174°C | |

| Heat deflection temperature (@ 0.45 MPa, 66 psi), ZX, XY | ASTM D648 Test Method A | 347°F/175 °C | |

| Heat deflection temperature (@ 1.82 MPa, 264 psi), XY, XZ, YX, YZ | ASTM D648 Test Method A | 237°F/114°C | |

| Heat deflection temperature (@ 1.82 MPa, 264 psi), ZX, XY | ASTM D648 Test Method A | 248°F/120°C |

GENERAL PROPERTIES

| Properties | Test Method | English | Metric |

| Powder melting point (DSC) | ASTM D3418 | 367°F | 186°C |

| Particle size | ASTM D3451 | 58 μm | 58 μm |

| Bulk density of powder | ASTM D1895 | 0.017 lb/in3 | 0.48 g/cm3 |

| Density of parts | ASTM D792 | 0.047 lb/cm3 | 1.3 g/in3 |

PA 12 W (PURE WHITE) TECHNICAL DATA

MECHANICAL PROPERTIES

| Properties | Test Method | English | Metric |

| Tensile strength, XY | ASTM D638 | 7106 psi | 49 MPa |

| Tensile strength, Z | ASTM D638 | 6526 psi | 45 MPa |

| Tensile modulus, XY | ASTM D638 | 275 psi | 1900 MPa |

| Tensile modulus, Z | ASTM D638 | 268 ksi | 1850 MPa |

| Elongation at yield, XY | ASTM D638 | 11% | 11% |

| Elongation at yield, Z | ASTM D638 | 8% | 8% |

| Elongation at break, XY | ASTM D638 | 17% | 17% |

| Elongation at break, Z | ASTM D638 | 9% | 9% |

| Impact strength (KJ/m2), XY | ASTM D256 | 4.8 | 4.8 |

| Impact strength (KJ/m2), Z | ASTM D256 | 4.1 | 4.1 |

GENERAL PROPERTIES

| Properties | Test Method | English | Metric |

| Powder melting point (DSC) | DIN EN/ISO 11357 | 370°F | 188°C |

| Particle size (D50) | DIN EN/ISO 8130/13 | 57 μm | 57 μm |

| Bulk density of powder | ISO 60 | 0.015 lb/in3 | 0.435 g/cm3 |

| Density, XY | ASTM D792 | 1.01 g/in3 | |

| Density, Z | ASTM D792 | 1.01 g/in3 |

PA 11 TECHNICAL DATA

MECHANICAL PROPERTIES

| Properties | Test Method | English | Metric |

| Tensile Strength, Max Load,11 XY, XZ, YX, YZ | ASTM D638 | 7542 psi | 52 MPa |

| Tensile Strength, Max Load,11 ZX, ZY | ASTM D638 | 7542 psi | 52 MPa |

| Tensile Modulus,11 XY, XZ, YX, YZ | ASTM D638 | 261 ksi | 1800 MPa |

| Tensile Modulus,11 ZX, ZY | ASTM D638 | 261 ksi | 1800 MPa |

| Elongation at Break,11 XY, XZ, YX, YZ | ASTM D638 | 50% | 50% |

| Elongation at Break,11 ZX, ZY | ASTM D638 | 35% | 35% |

| Flexural strength (@ 5%),12 XY, XZ, YX, YZ, ZX, ZY | ASTM D790 | 10150 psi | 70 MPa |

| Flexural modulus,12 XY, XZ, YX, YZ, ZX, ZY | ASTM D790 | 261 ksi | 1800 MPa |

| Izod impact notched (@ 3.2 mm, 23°C), XY, XZ, YX, YZ | ASTM D256 Test Method A | 5 kJ/m2 | 5 kJ/m2 |

| Izod impact notched (@ 3.2 mm, 23°C), ZX, ZY | ASTM D256 Test Method A | 4.5 kJ/m2 | 4.5 kJ/m2 |

| Shore Hardness D, XY, XZ, YX, YZ, ZX, ZY | ASTM D2240 | 80 | 80 |

THERMAL PROPERTIES

| Properties | Test Method | Temp | |

| Heat deflection temperature (@ 0.45 MPa, 66 psi), XY, XZ, YX, YZ, ZX, ZY | ASTM D648 Test Method A | 365°F/185°C | |

| Heat deflection temperature (@ 1.82 MPa, 264 psi), XY, XZ, YX, YZ, ZX, ZY | ASTM D648 Test Method A | 129°F/54°C |

GENERAL PROPERTIES

| Properties | Test Method | English | Metric |

| Powder melting point (DSC) | ASTM D3418 | 396°F | 202°C |

| Particle size | ASTM D3451 | 54 μm | 54 μm |

| Bulk density of powder | ASTM D1895 | 0.017 lb/cm3 | 0.48 g/in3 |

| Density of parts | ASTM D792 | 0.038 lb/cm3 | 1.05 g/in3 |

TPU 88A - BASF ULTRASINT TPU01 TECHNICAL DATA

MECHANICAL PROPERTIES

| Properties | Test Method | Typical Values XY-Direction | Typical Values Z-Direction |

| Tensile Strength/ MPa | DIN 53504, S2 | 9 | 7 |

| Tensile Elongation at Break / % | DIN 53504, S2 | 220 | 120 |

| Tear Resistance (Trouser)/ kN/m | DIN ISO 34 - 1, A | 20 | 16 |

| Tear Resistance (Graves)/ kN/m | DIN ISO 34 - 1, B | 36 | 32 |

| Tensile Modulus/MPa | ISO 527-2, 1A | 75 | 85 |

| Flexural Modulus/ kN/m | DIN ISO 178 | 75 | 75 |

| Compression Set B (23°C, 72h) / % |

DIN ISO 815 - 1 | 20 | 20 |

| Rebound Resilience / % | ASTM 2632 | 63 | 63 |

| Hardness Shore A | DIN ISO 7619 - 1 | 88 | 88 |

| Abrasion Resistance / mm³ | DIN ISO 4649 | 140 | 100 |

| Density | 1.1g/cm³ | ||

| Charpy Impact Strength (notched, -23 °C) / kJ/m2 | DIN EN ISO 179 - 1 | Partial Break | No break |

| Charpy Impact Strength (notched, -23 °C) / kJ/m2 | DIN EN ISO 179 - 1 | 21 | 29 |

| Rossflex testing (100k cycles, 23°C) | ASTM D1052 | No Cut Growth | |

| Rossflex testing (100k cycles, -10°C) | ASTM D1052 | No Cut Growth | |

| Vicat/A (10 N) / °C | DIN EN ISO 306 | 84 | 96 |

| UL Flammability | UL 94 | HB (1.6-4.2 mm) | HB (1.6-4.2 mm) |

ESTANE 3D TPU M95A TECHNICAL DATA

MECHANICAL PROPERTIES

| Properties | Test Method | Unit | Value Metric |

| Hardness (5 sec) | ISO 868 | Shore A | 95 |

| Specific Gravity | ISO 2781 | g/cm3 | N/A |

| Tensile Strength (XZ) | ISO 527 | MPa | 16 |

| Ultimate Elongation (XZ) | ISO 527 | % | 385 |

| Tensile Stress at (XZ) | N/A | N/A | N/A |

| -50 % Elongation | ISO 527 | MPa | 9 |

| - 100 % Elongation |

ISO 527 | MPa | 11 |

| - 300 % Elongation | ISO 527 | MPa | 30 |

| Tensile Strength (ZY) | ISO 527 | MPa | 19 |

| Ultimate Elongation (ZY) | ISO 527 | % | 240 |